In the industrial processes, cleaning is one of an important part which helps to keep equipment and surfaces free from contaminants. Although, best cleaning practice is unnecessary, resetting everything back to default.It's incredibly tedious on the part. That is where the revolutionary state-of-the art technology of laser cleaning comes into play and alters entirely how industrial cleansing has been practiced. Laser technology has ushered industrial cleaning into the modern world, by offering a quicker and safer method to clean parts.

The precision required while cleaning delicate and sensitive surfaces in industries is incomprehensible. This is where laser cleaning comes in handy because it can selectively remove undesirable materials from a surface without damaging the actual substrate, leaving an extremely clean area just at the target. So, this is the best option for handpiece to clean up machines and devices of electronics & optics and medical.

Standard sanitation measures can take a long time to complete, and also often require considerable human labor as well as resources. On the other hand, laser cleaning provides a low-touch surface cleaning which will deliver much higher productivity and efficiency whether in manual or automated processing. Moreover, its non-contact nature leads to increased safety in cleaning operations as no solvents, abrasives or other dangerous chemicals need be used for the process and hence reduce risk of frazzle-bag employees and environment respectively.

Laser Cleaning for Industrial Applications In industrial cleaning, laser-based methods clean the surfaces using intense high-energy light beams to remove contaminants including: Rust Paint Lubricants Grease A complete industrial laser rust cleaning machine consist of aLaser source, Delivery system and control unit. The laser source creates an intense light beam, and the delivery system consisting of optics, mirrors and lenses then aims this to the desired area. Power, beam modulation etc.- The Control Unit: Another critical parameter that has to be managed in order for the cleaning process to function efficiently as designed is regulating power or other functions needed during operations.

In the sphere of cleaning tasks, however laser technology changes industrial cleaning practices by becoming sustainable, affordable as well efficient. As a result, laser cleaning eliminates the use of toxic chemicals from industrial processes. It also reduces the need for expensive utensils and labor which is used to clean. Additionally, laser cleaning is much faster and efficient when compared to the traditional methods which accelerate overall productivity and efficiency provided by an industrial sector.

To sum it up the invention of laser technology has brought to an age in industrial cleaning, a method which is accurate and safe. Laser cleaning is also a versatile solution that can be used to clean every type of surface whether they are small and delicate or if one needs heavy-duty cleaning. Laser cleaning helps industries to improve productivity, environmental sustainability and safety level like never before.

We always adhere to the core values of "customer-centricity" and "creating customer-satisfying benefits." We put client service first on our concern list. We actively participate in the "Made in China 2025 initiative" making use of tools and services that assist modernize the Laser for cleaning effectively. Our company is afflicted with the dual forces Internet+ and Industry 4.0 to adapt ourselves to the needs of the internet era that are industrial. You are able to expect the fundamental laser that are advanced technology in addition to application service that one may find along with work with our partners to attain greater speeds, more economical and quicker development.

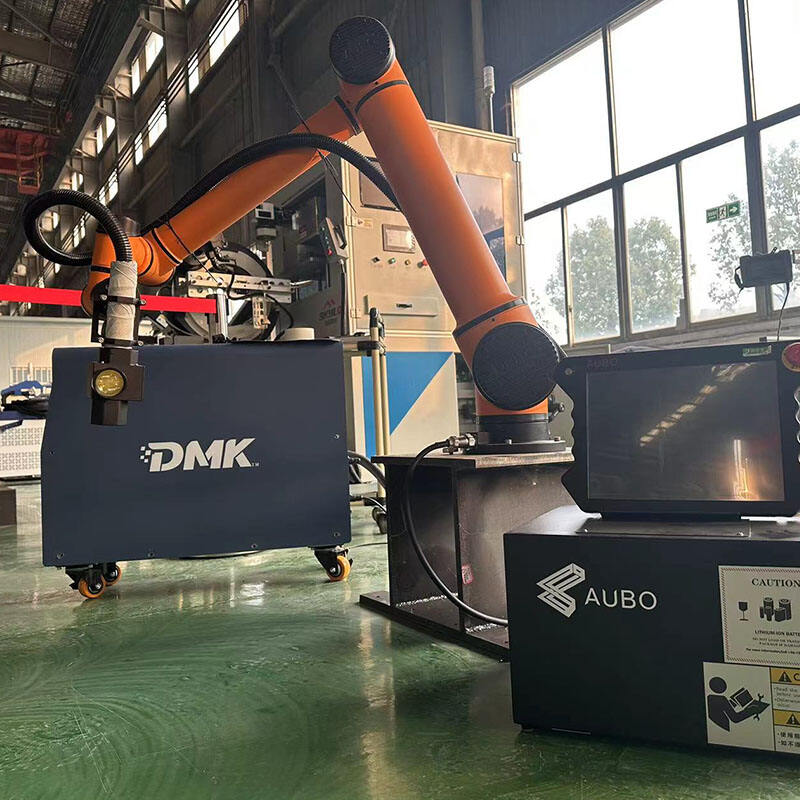

DMK try located in the East Lake High-tech Development Zone in Wuhan. We're the firm that try high-tech on developing, studies, production and purchases of complete laser equipment. We have significantly more than a dozen researchers and postgraduates on our creator's group. With the Laser for cleaning which are latest base and an experienced after-sales staff We could provide customized options for laser processing equipment which are automatic to both worldwide and domestic users. We provide professional after-sales help to help users resolve any issues which can be product-related.

With the constant development of fiber laser technology, we have included Laser for cleaning that is world-class and procedures. We partner with a few of the most reputable laser that are domestic and control system vendors like Raycus MAX, JPT Friendess Raytools SUP QILIN ESTUN. From the professional's view of laser processes, we carefully select every component of our equipment, strictly control construction processes, and conduct thorough inspections of the factory. We assist Chinese manufacturers to create better life for the world's consumers by this work.

Presently, our company has generated a supply chain that covers eight categories that are biggest an abundance of products, like machine that are complete of laser cutting equipment, laser welding machines because well since {keyword} additionally the method of getting components that are different since for instance fiber lasers cutting heads that cut lasers, welding minds also because laser cleansing minds also because laser control systems. Our items are commonly used in various industries such as for example sheet metal processing as well as environmental protection equipment which can be marine agricultural, aerospace, and the developing of new energy. The Middle East, Western Europe, and Russia with the ability to import and export goods separately our merchandise have really accumulated the market which keeps growing in worldwide areas such as for instance for instance East Asia, North America, Latin America.