Cleaning is a chore that can be so routine, monotonous and never-ending in our everyday lives. This gets even more trickier when it comes to the daunting task cleaning larve and resilent surfaces or articles. But what if there was a way to make the clean-up easier, faster and kinder on nature? This is where the amazing laser cleaning machine comes into play.

Saying Goodbye to Traditional Cleaning Methods With the Introduction of Laser Technology

Laser technology is a ground-breaking innovation that has revolutionized our approach to many tasks and cleaning in particular. We used traditional methods for cleaning like scrubbing and washing surfaces with chemical solutions to remove the dirt. These methods, however turned out to be slow and laborious at times as well not always eco-friendly.

Introduction of Laser Cleaning Technology The laser technology brings a paradigm shift in the cleaning method making it faster and efficientloyment. A laser can produce a high-intensity light beam, which means it can remove dirt (if you use that term loosely), rust or paint from surfaces without causing any harm. Besides, the use of laser cleaning is a safer option as it does not require harsh chemicals and eliminates intense physical labor.

The laser cleaning machines work with aid of high-powered beams that are used for removing dirt particles and other contaminants from surfaces. As the laser beam hits a surface it emits heat, vaporising any dirt in its way providing efficient cleaning.

These state-of-the-art machines can even be set according to the cleaning intensity required for that particular job. In doing so, they are fantastic at cleaning surfaces at a very small scale - meaning it can directly get rid of even the tiniest particles. Their flexibility also becomes a great advantage in case you need to reach tight spaces or clean an intricate object with curvy structures, for example.

With the highlighted features of using laser cleaning machines in industry, it is expected that soon every other person will be taking interest and start aiming to get these devices - as benefits are limitless. These are often used in industries like aerospace, automotive and manufacturing to clean large and complex machines as well areas that hard for reach.

Using a laser cleaning machine will increase productivity and decrease costs since it is the fastest way to clean something. In addition, it can help companies to meet environmental regulations by avoiding the utilization of toxic chemicals.

Although the initial cost of investing in laser cleaning machines will be high for businesses, they can benefit greatly from using them over time. They deliver quick cleaning of surfaces in seconds which saves you time and helps workers use their efforts elsewhere.

Moreover, the equipment allows eco-friendliness and cost savings in all environments as it does not require the use of chemicals or maintenance. They are also long-lasting than traditional cleaning equipment that often requires replacement when worn-out.

In short, the laser cleaner is a revolutionary solution for those who have to clean large and complex surfaces. This makes them an excellent resource for a wide variety of businesses because they provide safe, efficient and environmentally friendly cleaning.

The more information about laser cleaning machines becomes available, the higher are prospects of this method being used in a myriad number of industrial processes. These high-tech gadgets are now considered a game changer in cleaning, as this method will not only save time and money but also allow for using less- harmful chemicals to contribute good things in terms of environmental friendly.

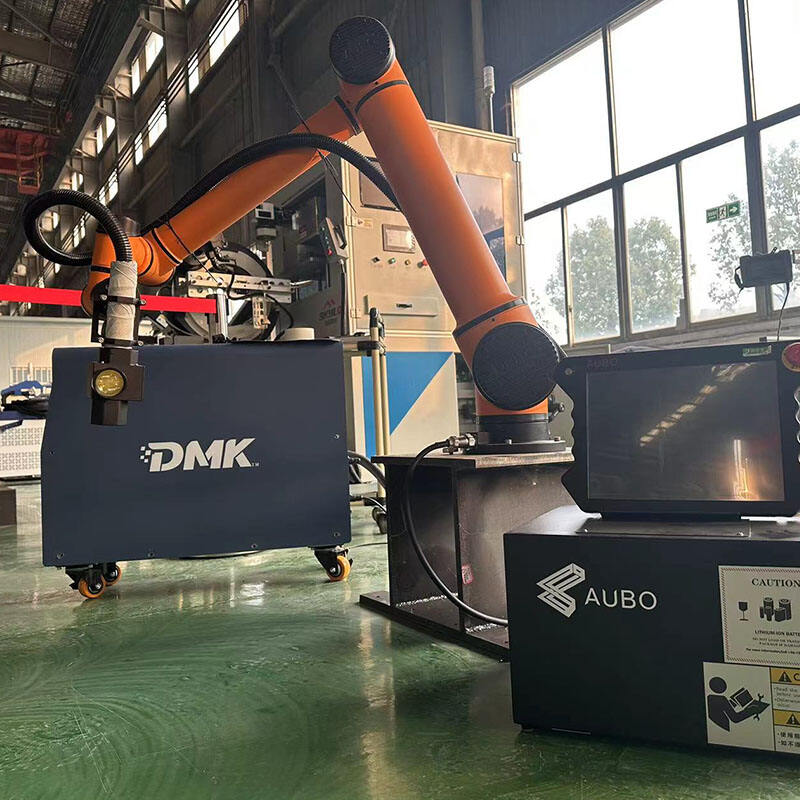

DMK try situated in the East Lake High-Tech Development Zone (Optics Valley) positioned in Wuhan, China. Our company is a company that are highly-tech are expert in research, development, and manufacturing of complete sets of laser equipment. We now have a few dozen postgraduates and researchers in our creator's team. With our contemporary manufacturing center for laser equipment, along with a skilled staff that is after-sales can afford to provide custom solutions for Laser cleaning machine processing equipment to domestic and worldwide users. We offer the professional service which was after-sales resolve any product-related problems quickly.

We always adhere to the core values of "customer-centricity" and "creating customer-satisfying benefits." We put client service first on our concern list. We actively participate in the "Made in China 2025 initiative" making use of tools and services that assist modernize the Laser cleaning machine effectively. Our company is afflicted with the dual forces Internet+ and Industry 4.0 to adapt ourselves to the needs of the internet era that are industrial. You are able to expect the fundamental laser that are advanced technology in addition to application service that one may find along with work with our partners to attain greater speeds, more economical and quicker development.

Our company presently includes a supply chain that features eight major kinds of goods and loads of items, such as for instance for example machines which are complete can be used for laser cutting, laser welding, and laser cleansing, in choice to equipment like {keyword} in addition to laser heads. Our items can be used in industries such as for instance for instance sheet metal processing protection which is also ecological vessels, agricultural equipment, aerospace, in choice to power which is new. Our products, that are able to export and import individually and are growing in the share of forex trading that are regions which are global because East Asia, North America and Latin America, Middle East, Western Europe and Russia.

We have integrated the laser technology that is latest into our processes. In collaboration with top suppliers in the US of lasers and control systems such since Raycus, MAX, JPT, Friendess, Raytools, SUP, QILIN, and ESTUN We are committed to supply the market with low-cost laser cutting, welding, cleaning, cladding, and marking equipment. We choose very carefully the elements which get into our laser equipment, manage assembly procedures, and conduct factory which is rigorous. Using this method, we permit Laser cleaning machine to supply a best constantly enjoy for each of our customers across the world.