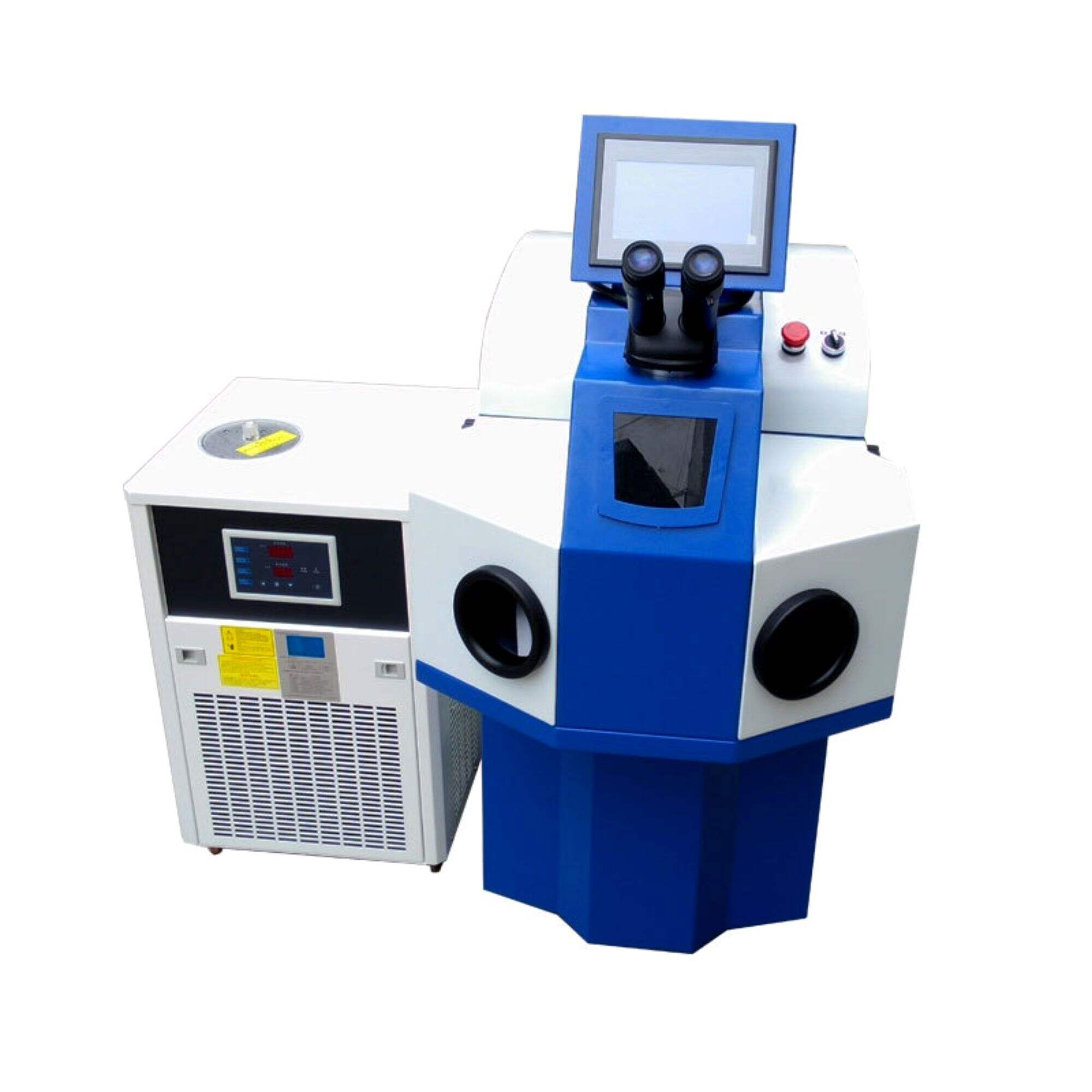

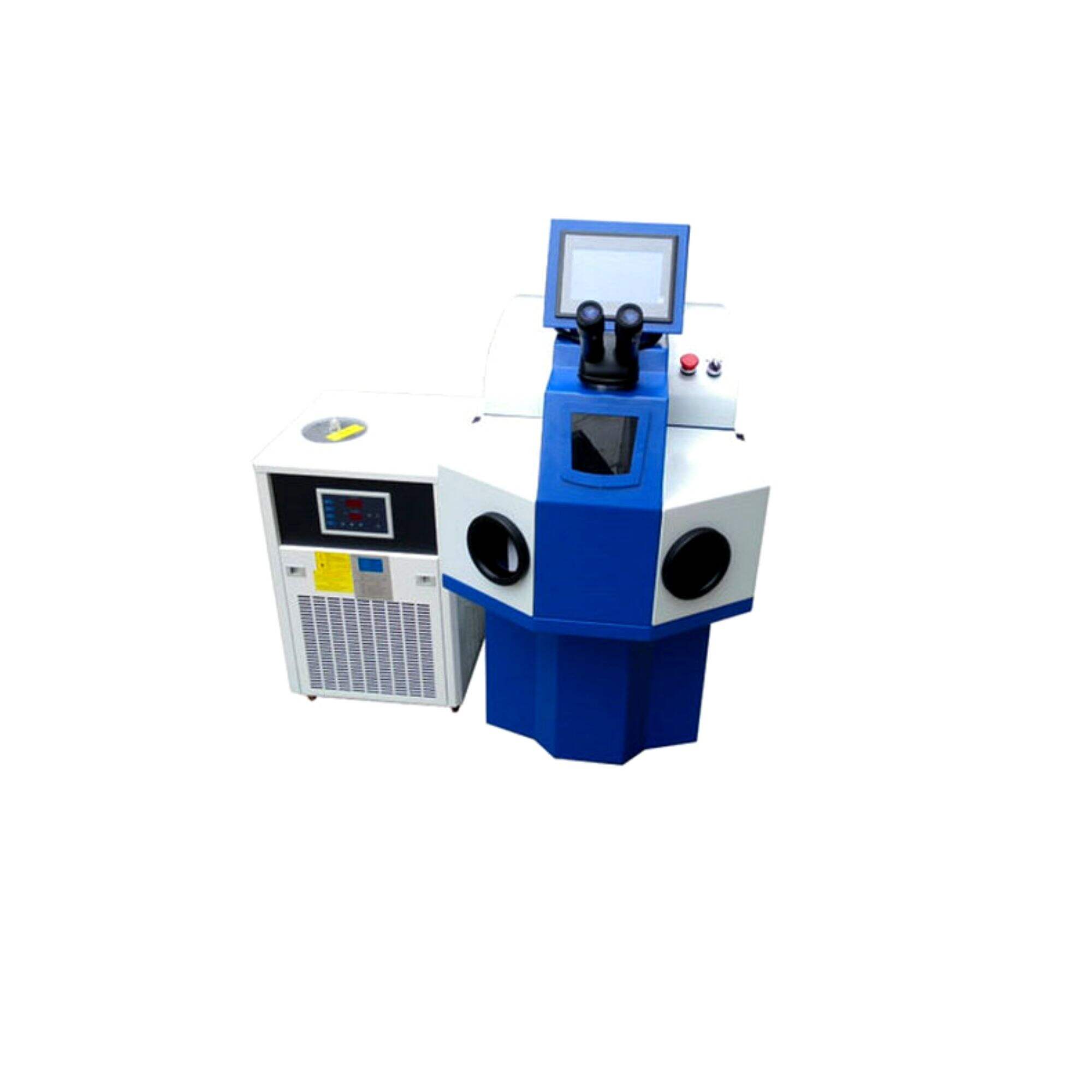

200W Jewelry Spot Welding Machine Laser Welders For Metal Soldering Machine For Gold Silver

| Product Description |

|

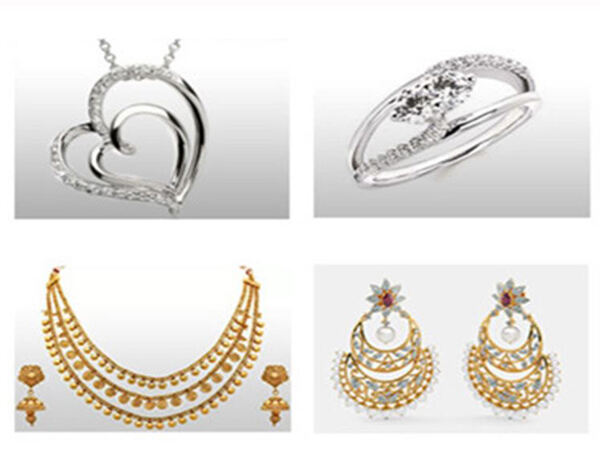

Laser spot welding is an essential part of the laser materials processing technology application, which belongs to heat conduction type. That is the surface of the workpiece heated by laser radiation, heat diffuses inside through heat conduction, by controlling the parameters of laser pulse width, energy, peak power and repetition frequency, the workpiece is melted to form a specific molten pool. For its unique advantages, laser spot welder has been widely used in the processing of jewelry and welding of micro or small components. The laser spot welder is applied to jewelry ornaments manufacturing, jewelry repairing, rings or bracelets resizing, gold and silver re-tipping, stone setting, eyewear welding or repairing, denture welding, small auto parts welding, etc. Generally, it is especially suitable for tiny target precision welding. It works on gold, platinum, titanium, silver, copper, nickel, aluminum, magnesium, stainless steel, etc. |

|

| Application & Samples |

|

Features: 1. Integrated Chiler,Save Space,Save Shipping Cost 2. High Quality,imported CeramicCavity 3. Touch Screen, easy to operate |

|

Features: 5. Water Cooling System, Anours working 6. Long time span, 100000hours 7. Widely use, for most meta!materal |

|

| Technical Parameters |

| Model | DWJ-150 | DWJ-200 |

| Laser Source | Nd3: YAG | Nd3: YAG |

| Rated Laser Power | 150W | 200W |

| Laser Wavelength | 1064nm | 1064nm |

| Power Consumptionc | 5KW | 6KW |

| Focal Spot Diameter | 0.1-3mm | 0.1-3mm |

| Focal Length | 100mm | 100mm |

| Laser Pulse Frequency | ≤50Hz | ≤50Hz |

| Laser Pulse Width | 1.5-20ms adjustable | 1.5-20ms adjustable |

| Shield Gas Connection | 1 line quick connection (argon) | 1 line quick connection (argon) |

| Cooling System | Water Cooling | Water Cooling |

| Power Supply | 220V single phase/50Hz/20A% | 220V single phase/50Hz/20A% |

| Continuous Working Time | 24hrs | 24hrs |

| Features |

|

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR