- Главная страница

- Продукты

- О НАС

- ВИДЕО

- Применение

- Новости

- Центр помощи

- СВЯЖИТЕСЬ С НАМИ

Сегодняшнее обновление сосредоточено на безопасности и защите лазеров. С широким использованием лазерной технологии в резке, сварке, маркировке и облицовке, многие традиционные отрасли промышленности приняли лазеры.

СВЯЖИТЕСЬ С НАМИ

Сегодняшнее обновление сосредоточено на безопасности и защите лазеров. С широким использованием лазерной технологии в резке, сварке, маркировке и облицовке, многие традиционные отрасли промышленности приняли лазеры. Однако многие инженеры и квалифицированные работники не имеют необходимой

Сами лазеры не являются по своей сути опасными, но безопасность может быть обеспечена путем принятия соответствующих мер защиты. поэтому мы надеемся, что эта научно-популярная статья повысит осведомленность среди интеграторов лазерного оборудования, продавцов лазерных продуктов, руководителей производства на передовой линии и

Обучение безопасности лазера имеет решающее значение для безопасности и эффективности лазерной сварки. во время процесса лазерной сварки вырабатывается сильный свет, тепло и вредные газы, создающие риски для здоровья операторов. Благодаря обучению инженеры и операторы могут научиться правильно использовать средства индивидуальной защиты, такие как защит

Основные опасности лазеров включают следующие:

1) тепловые эффекты: лазерный луч генерирует тепло, которое может вызвать ожоги кожи и глаз.

2) акустические эффекты: лазеры производят механические ударные волны, подобные водяным волнам, которые могут вызвать локальное испарение и повреждение тканей.

3) фотохимические эффекты: определенные длины волн лазерного света могут вызывать химические реакции в тканях, которые могут привести к катаракте, ожогам роговицы или сетчатки и повышенному риску развития рака кожи.

В зависимости от типа лазера, длительности импульса, количества повторений и длины волны, воздействие лазеров на кожу может варьироваться от легкого покраснения и боли до серьезных ожогов третьей степени.

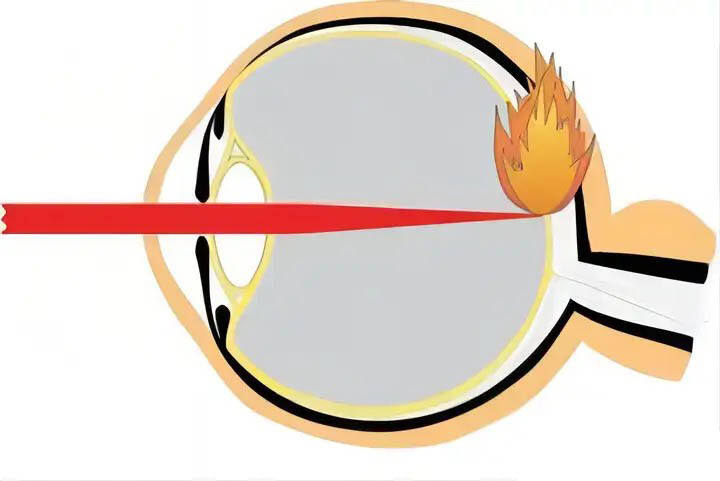

Влияние лазеров на глаз зависит от ряда факторов, включая размер зрачка, пигментацию, продолжительность и повторение лазерного импульса и длину волны. Различные длины волн лазерного света проникают в глаз на разных уровнях, вызывая повреждение ро

Высокие температуры, генерируемые лазерами, могут мгновенно свернуть или испарить белки, вызывая повреждение биологических тканей. Глаз является одним из самых чувствительных органов к лазерному воздействию. из-за фокусирующего эффекта глазного яблока плотность

Различные длины волн лазерного света могут повредить разные части глаза, потому что прозрачность глаза варьируется в зависимости от длины волны. Поэтому наблюдение за процессом сварки лазером без защитных очков может привести к необратимым повреждениям глаз.

Из-за фокусирующего эффекта человеческого глаза даже слабый внешний свет, попадающий в глаз, фокусируется, увеличивая его плотность энергии и вызывая большее повреждение глаз.

Инфракрасный свет, излучаемый лазерами, может вызвать значительные повреждения человеческого глаза, сжигая сетчатку и приводить к потере зрения или даже слепоте. когда луч проникает в зрачок, он проникает в линзу и фокусируется на сетчатке, в частности на маку

Поскольку инфракрасный свет невидим, глаз не может мигать в ответ, что позволяет лазеру продолжать проникать в зрачок и наносить больше вреда, чем видимый свет. поэтому необходимо носить защитные очки при эксплуатации лазерного оборудования, и, если возможно, рекомендуется защита всего тела.

Когда помещение слабо освещено, зрачки расширяются, чтобы позволить большему количеству света проникать, что позволяет более четко наблюдать за окружающей средой. если лазерное излучение присутствует в таких условиях с низким уровнем освещения, количество лазера, попадающего в глаза, увеличивается, что

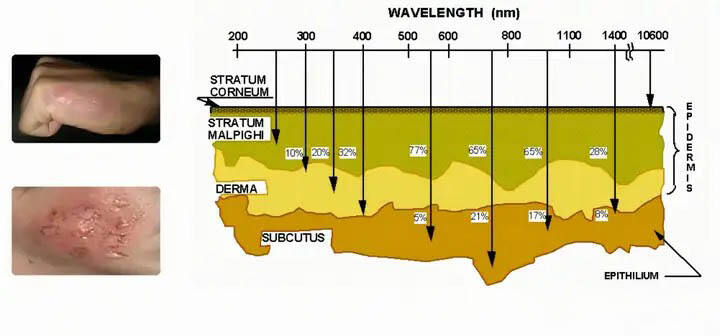

Опасности лазеров для кожи:

Различные длины волн лазерного света проникают в кожу на разную глубину (как показано на диаграмме выше).

В целом, чем длиннее длина волны, тем больше способность проникновения. при 400 нм глубина проникновения лазера не превышает 1 мм и может достичь дермы; при 514 нм глубина проникновения лазера составляет примерно 0,5 мм до 2 мм; при 630 нм глу

Как правильно защитить себя от лазеров:

Очки с лазерной защитой используются для ослабления лазерного излучения и защиты глаз. очки должны соответствовать следующим специальным требованиям:

1) Соответствие национальным стандартам : защитные очки с лазером должны быть одобрены и маркированы в соответствии с национальными стандартами.

2) Применимые сценарии : очки должны быть подходящими для типа лазера, длины волны, режима работы (непрерывный или импульсный) и настройки мощности.

3) Видимая маркировка : защитные очки должны быть четко помечены, чтобы гарантировать правильный выбор очки для конкретного лазера.

4) Защитная способность : рама и боковые части очков должны обеспечивать некоторую защиту.

Автоматические светоизменяющие сварочные маски

Сварные операции : с точки зрения сварных операций автоматические светоизменяющие сварные маски обеспечивают сварщикам четкое зрение перед сваркой, помогая им точно распознавать сварные соединения и избегать слепой и голой сварки. во время работы маска меняет свет в 0,1 миллисекунды при комнатной

Безопасность и здоровье : с точки зрения безопасности и здоровья, автоматическая светоизменяющаяся сварочная маска обеспечивает надежную защиту глаз и лица. она предотвращает травмы, такие как тепловое трещины черного стекла и воздействие вредного светового излучения. кроме того, она уменьшает утомление глаз и физи

Автоматическая переменная световая сварочная маска является не только защитным устройством, но и незаменимым инструментом в сварочных операциях. она значительно повышает качество и эффективность сварочной работы и обеспечивает более сильную защиту безопасности сварщиков. это важный результат современного научно-технического развития.

Выбор защитной одежды с лазером

Перчатки или специальная одежда : для уменьшения воздействия на кожу при выборе защитной одежды следует учитывать следующее:

1) обеспечить соответствующую защитную одежду: по возможности обеспечить соответствующую защитную одежду для персонала, подвергающегося воздействию излучения, превышающего значение mpe (максимально допустимого воздействия) на кожу.

2) материалы: защитная одежда должна быть изготовлена из подходящих огнестойких и теплостойких материалов.

3) охват: защитная одежда должна максимально уменьшить воздействие на кожу.