6000W Buizenlaserweldset voor Productielijn

Productomschrijving

Dit set biedt een uitgebreide, geautomatiseerde laserschweioplossing die is ontworpen voor buisschweiwerk op productielijnen. Door een geavanceerd handhavingschweiapparaat te combineren met een 6000W lasersysteem, maakt het hoge precisie en efficiënte automatische schweiing mogelijk, wat de productie-efficiëntie en de kwaliteit van de schwei aanzienlijk verbetert.

Productcomponenten

-

Communicatiekabel & Glasvezel (20m)

Garandeert stabiele signaaloverdracht en laserstraalbesturing, waardoor efficiënte communicatie en nauwkeurige lasercontrole tijdens het schweiën wordt ondersteund. -

Laserbron (RFL-C6000S-CE)

De 6000W laserbron is ideaal voor de meeste industriële schweiapplicaties. Met sterke stabiliteit en aanpasbare vermogenuitkomst kan deze gemakkelijk dikke wanden en hoogsterkte metalen verwerken. -

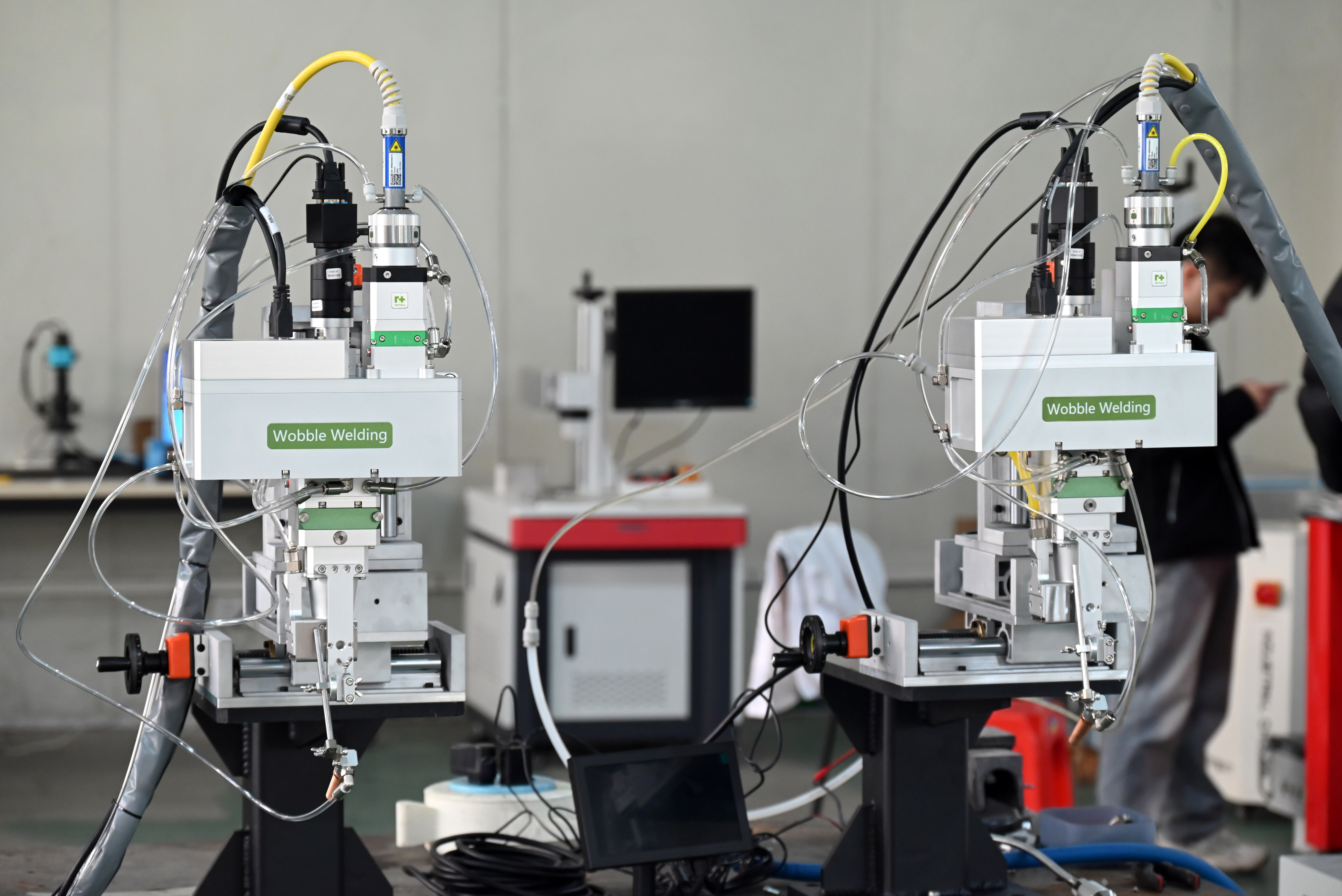

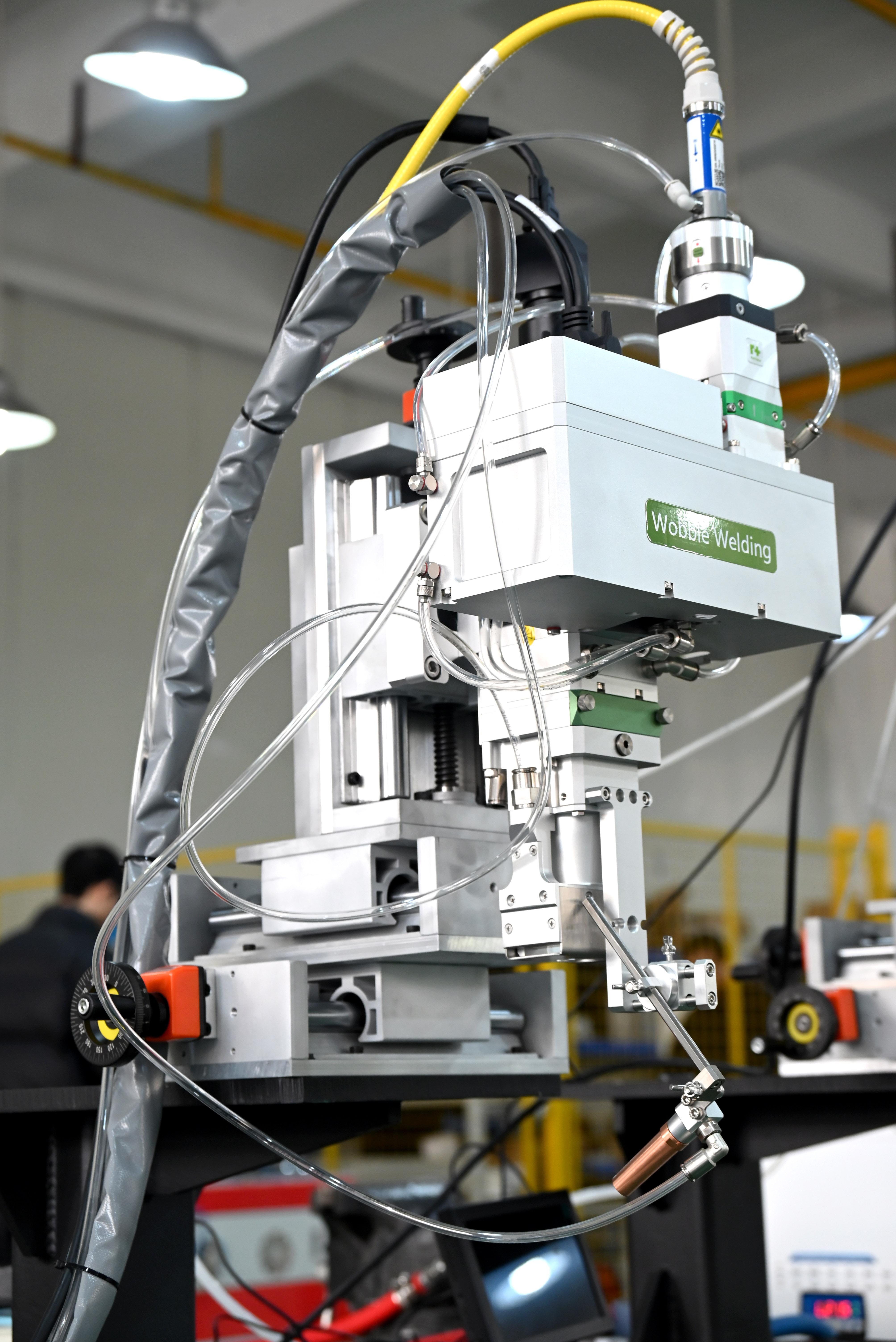

Lasbrander (BF330-6F + Bedieningskast)

Uitrusting met de BF330-serie automatische lasbrander en bedieningskast, zorgend voor nauwkeurige positieering en operatie. De lasbrander heeft de volgende kenmerken:- Uitmuntende schweikwaliteit:

Lage porosititeit, hoge mechanische prestaties en hoogwaardige lasoppervlakken voor consistent, gladde lassen. - Rijke Scanpatronen:

Continue lasondersteuning voor verschillende patronen, inclusief cirkelvormig, vierkant, recht, ovaal, C-vorm, S-vorm en 8-vorm, wat aan diverse lasbehoeften voldoet. - Uitbreidbare Modules:

In staat om temperatuursensoren, nadenvolging of positioneringsmodules toe te voegen, waardoor er eenvoudige automatisatieintegratie mogelijk is voor verbeterde flexibiliteit in de productie. -

Laad-Type Spiegelhouder:

Snel en eenvoudig vervangen van beschermende lenzen, wat het onderhoudsefficiëntie verbetert.

- Uitmuntende schweikwaliteit:

-

Las Kop Houder (Handmatige XYZ As)

Biedt flexibele aanpassing van de positie van de laskop met behulp van de handmatige XYZ as, waardoor er gemakkelijk kan worden aangepast aan verschillende werkhoeken en -omgevingen. -

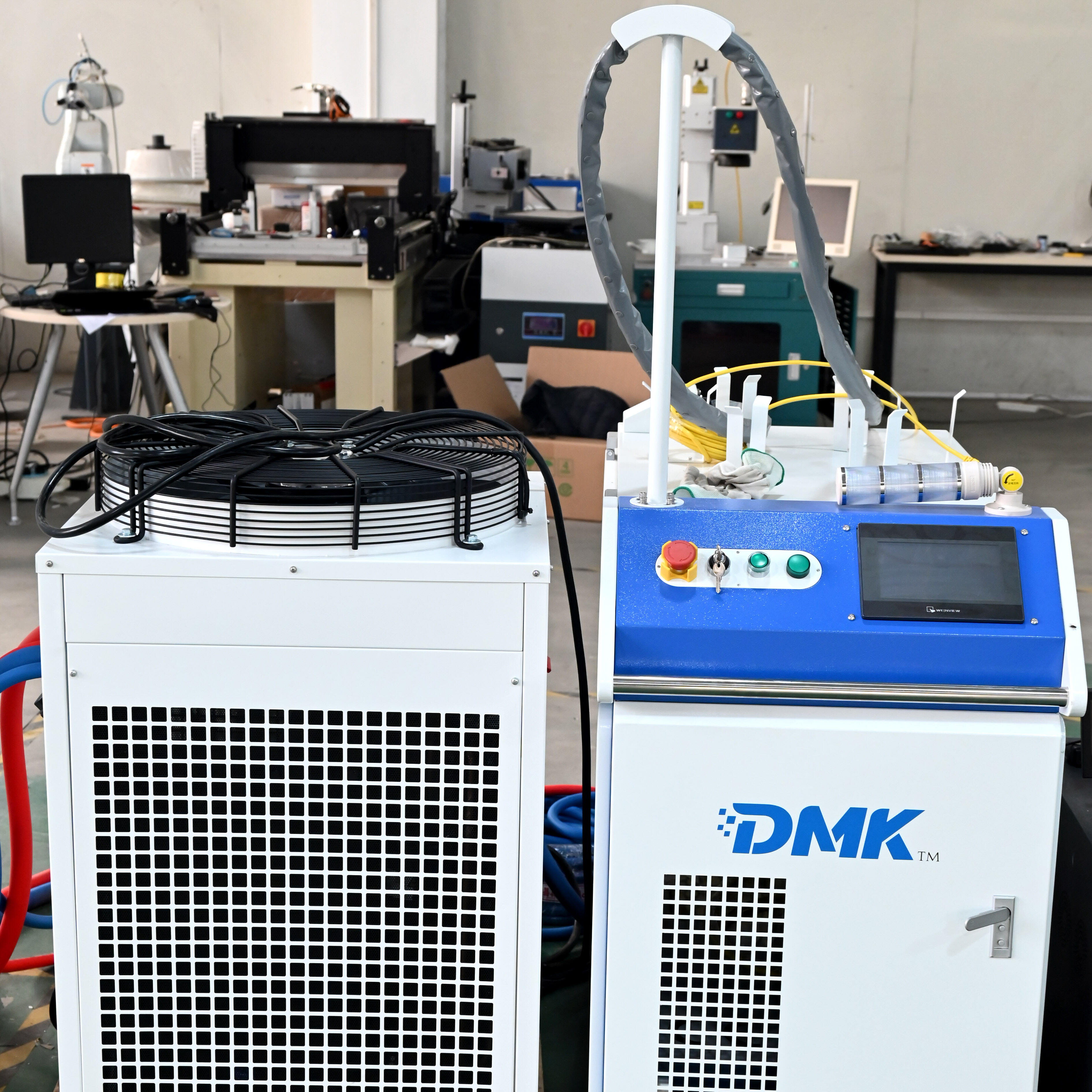

Koelsysteem (HL6000)

Efficiënt koelsysteem dat actief de temperatuur van het laskop en de lasersource verlaagt, zorgend voor een stabiele werking gedurende lange werkuren en voorkomend oververhitting. -

Lascontrolekast (Controlesysteem + Elektrisch Systeem)

Urustgerust met een efficiënt en stabiel lascontrolesysteem voor nauwkeurige procescontrole. Inclusief elektrische onderdelen voor eenvoudige integratie in de productielijn, aangepast aan verschillende stroomvereisten. -

Elektrische Onderdelen (Driefasen Spanningsregelaar met Fasevolgorde- en Uitvalbescherming)

Garandeert stabiele werking bij aansluiting op verschillende stroombronnen, met fasevolgorde- en uitvalbescherming voor verbeterde veiligheid en duurzaamheid van de apparatuur.

Productkenmerken

- Hoogvermogen laserbron:

De 6000W laserkracht is geschikt voor precisielassen in grote schaalproductie, gemakkelijk dikke materialen en hogersterkte metalen verwerken. - Gautomatiseerd Laskop:

Bij gebruik met de handhafde laserweldmachine stelt het automatische weldkop het in staat om assemblylijn-welding te stroomlijnen, wat zowel efficiëntie als precisie verbetert. -

Slim Systeem voor Bediening:

Eenvoudige bediening met nauwkeurige controle over het weldproces, wat een consistente weldkwaliteit waarborgt.

- Efficiënt Koelsysteem:

Het geïntegreerde waterkoelsysteem beheert de temperatuur effectief, waardoor er continu op hoge vermogen kan worden gewerkt zonder oververhitting. - Hoog Stofweerstand:

De betrouwbare afsluitingsontwerp van de weldkop houdt stof erbuiten, wat de duurzaamheid en levensduur van de apparatuur verhoogt. - Snel Lenswissel:

De laadstijl spiegelhouder vereenvoudigt het proces van het vervangen van beschermende lenzen, wat onderhoud gemakkelijker en sneller maakt. - Elektrische Bescherming:

Het systeem bevat ingebouwde elektrische bescherming, wat veilige bediening waarborgt onder verschillende omstandigheden.

|

|

Toepassingen

Dit set is perfect voor industrieën die hoge kracht en hoge precisie vereisen bij automatische laswerkzaamheden, vooral in toepassingen zoals buislassen, metaalbewerking, automobielbouw en machinefabrikatie . Of het nu gaat om massa-productie of precisielasopdrachten, dit set biedt een zeer efficiënte oplossing.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR