dmk tragbare Handschweißmaschine mit Faserlaser

Übersicht

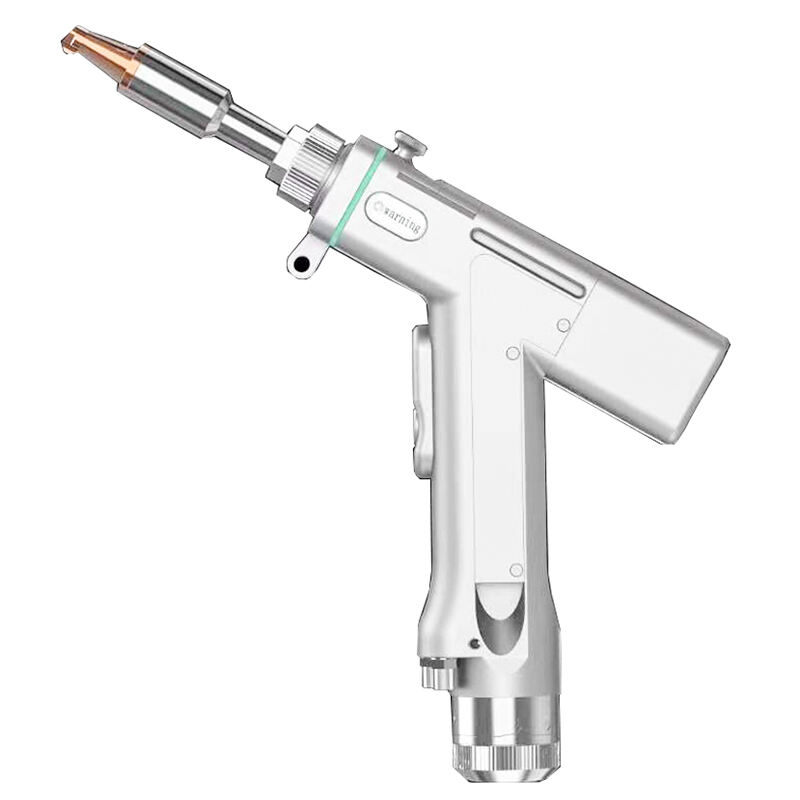

Die Handlaserschweißmaschine besteht aus einem Schrank, einem kontinuierlichen Faserlaser, einem Kühlwasserzirkulationssystem, einem Lasersteuerungssystem und einem handheld-Schweißkopf. Dieses Produkt kann Metallmaterialien wie Kohlenstoffstahl, Edelstahl, Aluminiumlegierung usw.

Spezifikation

| Lasertyp | Faserlaser |

| Laserquelle | max/raycus/reci |

| Laserleistung | Die Leistung der Fahrzeuge ist in der Regel von der folgenden Größe: |

| Laserwellenlänge | 1080 ± 10 nm |

| Instabilität der Ausgangsleistung | < 2% |

| Ausgangsleistungsstimmigkeit | 10 bis 100% |

| Glasfaserlaserlänge | Standard 10m / 15m / 20m |

| Kühlweise | Wasser-Kühlung |

| Kühlmedium | Wasser, das von der Herstellung oder Verarbeitung von Wasser oder von anderen Stoffen hergestellt wird, |

| Tankkapazität | 13l/16l |

| Laserkopf | Gefassst sup/relfar/qilin |

| Laser-System | Gefassst sup/relfar/qilin |

| Schwankbreite | 0-6 mm |

| Stellgröße | < 5 mm |

| Schweißmodus | Gerade Linie, Fischschuppen, Fleck |

| Hilfsgas | Stickstoff/Argon |

| Reinigungsbreite | 40mm |

| Spannung | 220V/380V/auf maßgeschneiderte Weise |

für mehr Teile

|

Laserquelle Wir verwenden Max/Reci/Raycus, eine weltbekannte Laserquelle von höchster Qualität, mit ausgezeichneter Strahlqualität. |

|

Schweißpistole Sup/gefasst 3 in 1 Version, unterstützt Schweißreinigung und Schneiden. Es ist in der chinesischen Schweißpistole mit hoher Qualität an erster Stelle. |

|

|

|

Automatischer Drahtzufuhr Es wird für die automatische Wiederauffüllung von Schweißdraht verwendet, mit einem unabhängigen Touchscreen mit 19 Sprachen, ist bequemer, die Drahtzufuhr zu steuern.

|

|

|

s&a/hanli-Kühler Wir verwenden die professionellsten Kühler. Es ist für das Laserschweißen spezialisiert. Die Temperaturkontrolle erreicht 0,5 °C. |

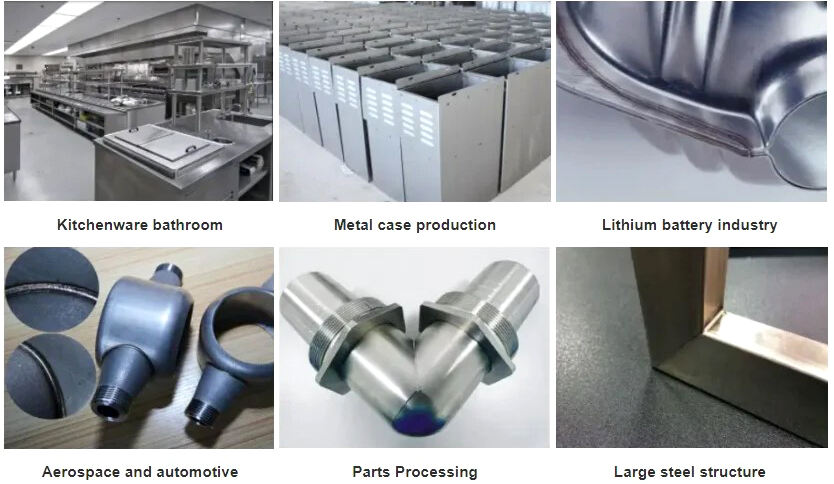

Anwendung

Die Funktionen einer handgeführten Laserschweißmaschine sind:

Präzisionsschweißen : Handschweißmaschinen mit Laserschweiß ermöglichen ein hochpräzises Schweißen, das für verschiedene Metallmaterialien, insbesondere für dünne Bleche und komplexe Formen, geeignet ist.

Erhöhte Effizienz : im Vergleich zu herkömmlichen Schweißverfahren bieten handgeführte Laserschweißmaschinen schnellere Schweißgeschwindigkeiten und erhöhen so die Produktionseffizienz erheblich.

Verringerte thermische Verformung : die kleine Wärmezone beim Laserschweißen minimiert die Materialverformung während des Prozesses und sorgt für eine hohe Schweißqualität.

flexibler Betrieb : die Handkonstruktion ermöglicht einen flexiblen Betrieb, wodurch das Schweißen in verschiedenen Positionen und Winkeln erleichtert wird.

Niedrige Wartungskosten : Laserschweißmaschinen sind sehr langlebig mit geringen Wartungskosten und bieten langfristige Wirtschaftlichkeit.

Umweltfreundlich : Das Laserschweißen erzeugt weniger Rauch und verbraucht weniger Energie, was es umweltfreundlicher macht.

Verpackung & Lieferung

|

|

Unternehmensvorstellung

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR